Engineering and Design Contractor to the Bike Industry

Crafting the Future of Bike Design, Today

We design bikes with tomorrow in mind, blending cutting-edge technology and performance to shape the future of cycling and mobility.

tools

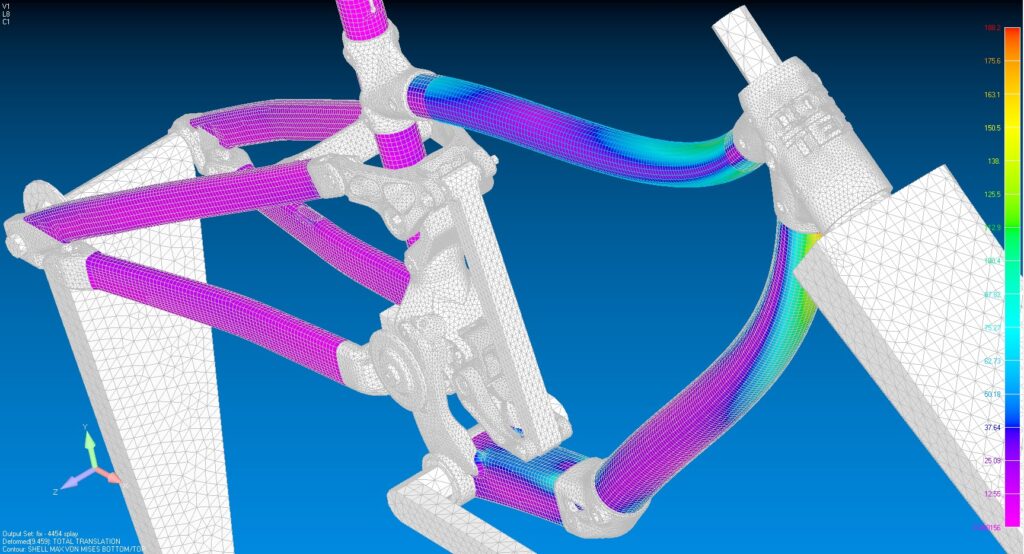

Structural Engineering

All our frame designs are subject to twelve unique load scenarios, each representing a common high-load riding condition. O'Connor Design utilizes a Finite Element Mesh, which contains a mixture of solid and shell elements and approximately one million nodes (3M D.O.F). This detailed analysis creates a robust global picture and ensures correct transfer of loads to the individual moving parts.

Creo Specialist

All bikes and parts are designed using PTC Creo, a top-tier 3D modelling software. With twenty years of experience, mastering this tool, O'Connor Design can offer rapid turnaround on multiple frame sizes and projects.

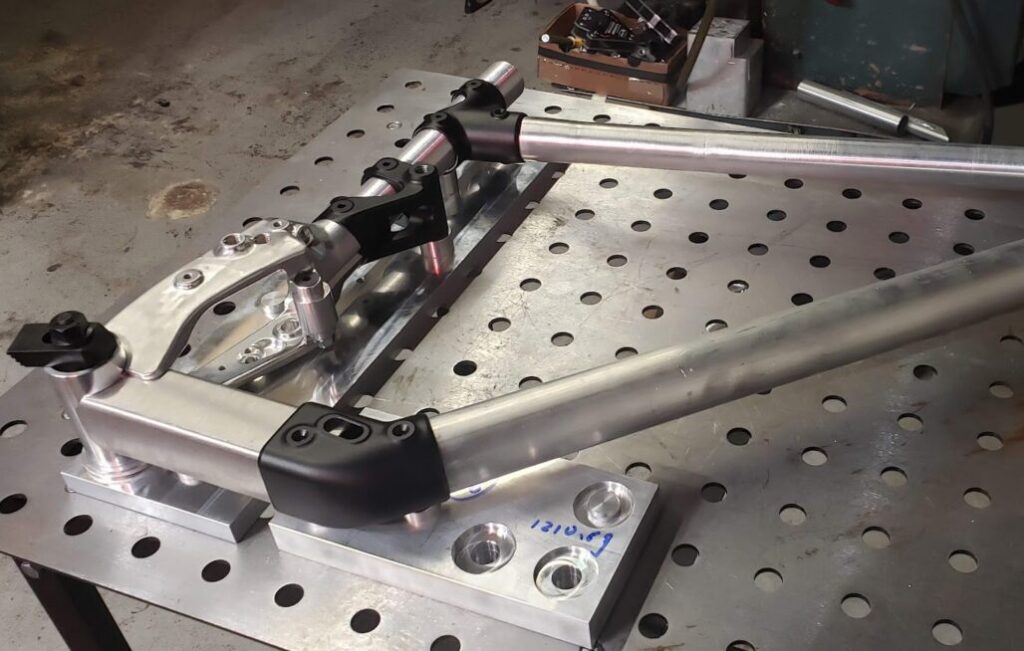

Mule frame fabrication

Our mule frames are crafted in-house using a welded and bonded lug frame design. This method ensures precise pivot point placement while minimizing distortion from welding, preserving accurate frame geometry. We utilize off the shelf tubes for quick prototyping, all while maintaining the desired torsional stiffness, which is validated through extensive FEA analysis using FeMap and Nastran software. The typical turnaround time for a complete frame is approximately two months.

CNC

Backed by ten years of machining experience, from intricate parts to full mule frame fabrication, O’Connor Design can create an optimized product ready to manufacture.

Kinematics expert

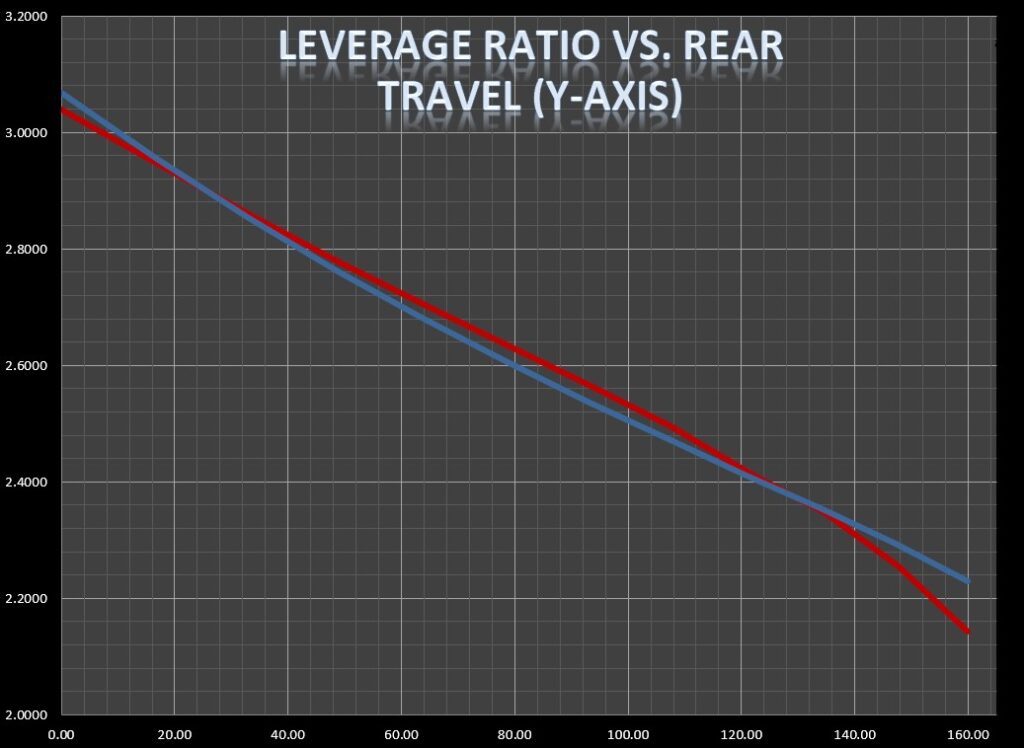

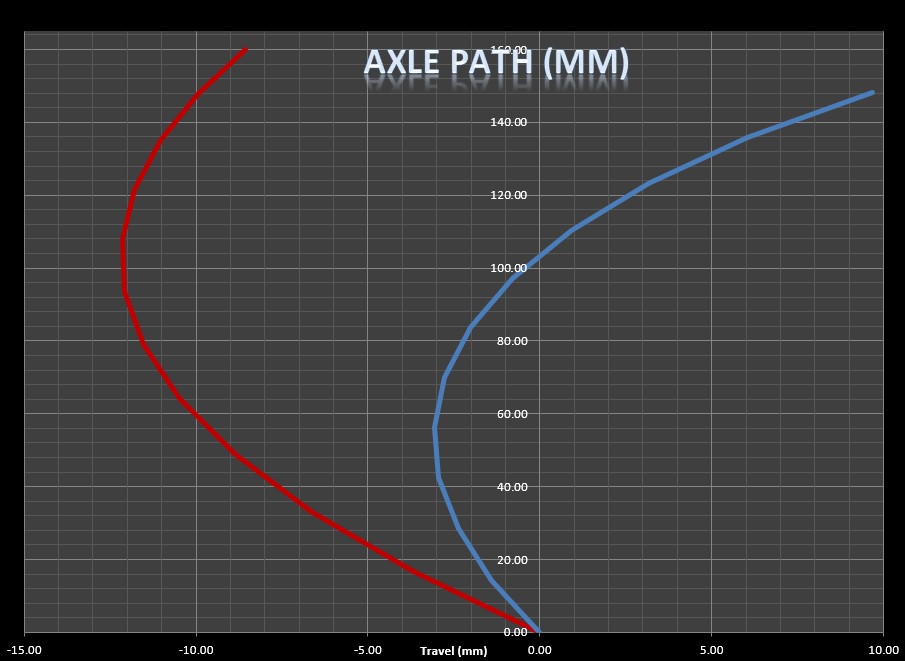

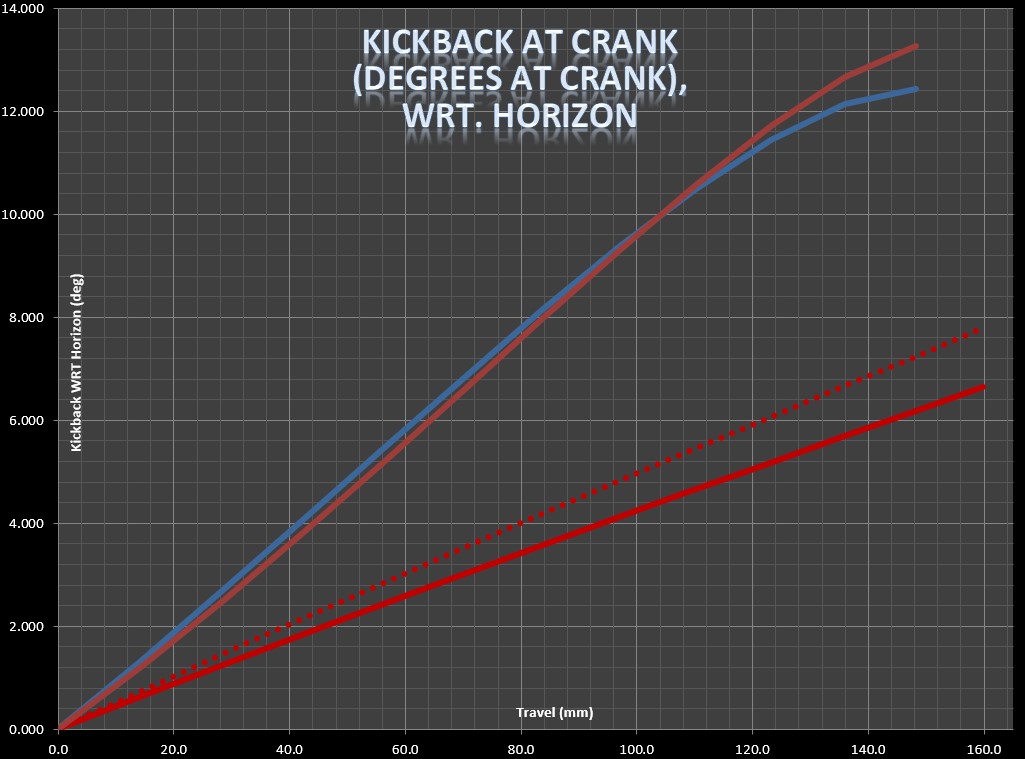

At O’Connor Design, we specialize in frame optimization through advanced kinematic theory. Our approach allows us to simultaneously develop multiple unique linkage layouts—such as co-rotating and counter-rotating linkages—while maintaining the same kinematic properties for each layout. By easily adjusting pivot points during the design process without altering kinematic properties, we achieve precise linkage optimization.

O’Connor Design has also invented a new 6-bar suspension layout, currently patent-pending (US 2024/0286705 A1). This innovative design is applicable to both the rear suspension of 2-wheel vehicles and the linkage mechanism of 4-wheel vehicles. The key innovation of this patent is its ability to isolate wheel trajectory from the leverage curve’s shape and slope—something traditional 4-bar linkages cannot achieve. This flexibility allows for a kinematic system that can be finely tuned for each parameter without compromise.